Informative Links

- Test Fixture and MEMS Test Fixture Design

- Circuit Design

- Semiconductor Fab Equipment Design

- Instrument Design for the Chemical, Biotech and Life Sciences Industry

Portfolio of

Example Projects

LED Test Fixtures

The following pictures are of LED test fixtures and contactors for making electrical contact to LEDs designed by Henning Engineering. These are good examples of the skill and attention to detail that we can apply to your application. LED test fixture design requires good electro-mechanical design skills as well as some knowledge of optics. All of the fixtures shown are designed to be interfaced to an integrating sphere and are custom designed to be used with high current large die LEDs. The fixtures are capable of forward currents in the range of 5A up to 40A. Making reliable contact at these currents while also keeping the emitting surface unobstructed required some very low profile high current connection schemes.

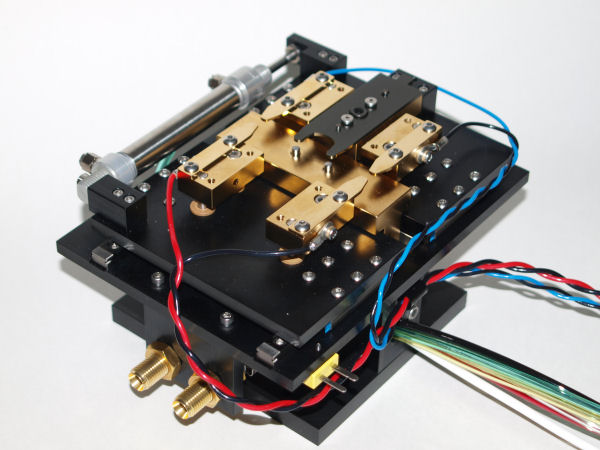

Test fixture for testing high current LEDs. Fixture is water cooled and can test up to 40A of forward current

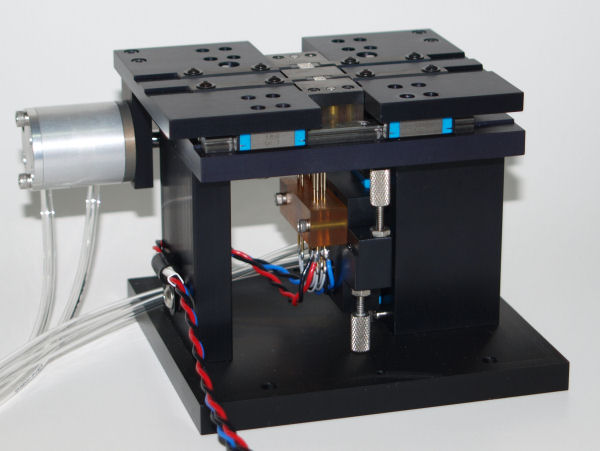

Test fixture for testing smaller surface mount LEDs.

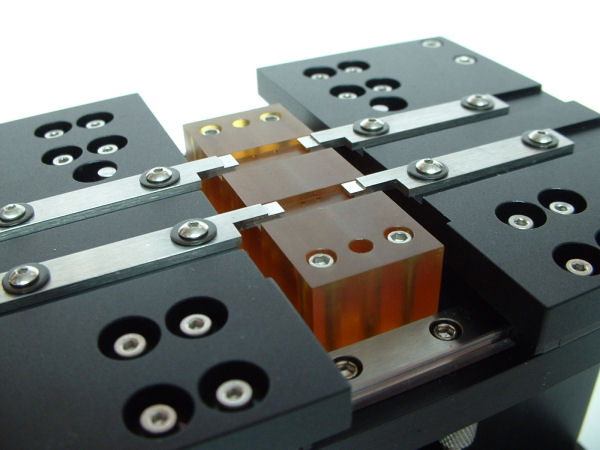

Close up view of test fixture for testing surface mount LEDs.

Special high current manual "clip" connector for making electrical contact while testing high current LEDs. Connector has both force and sense contacts.

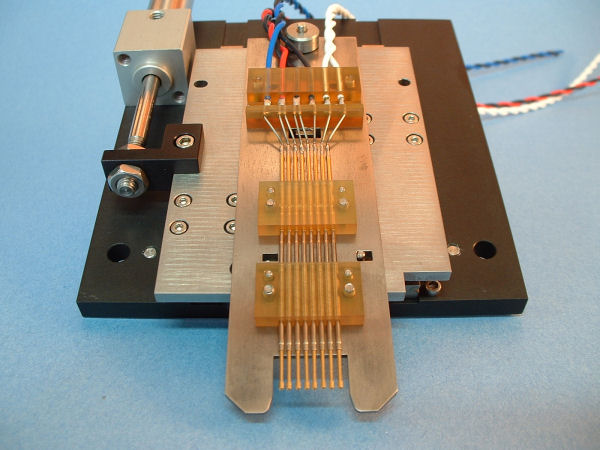

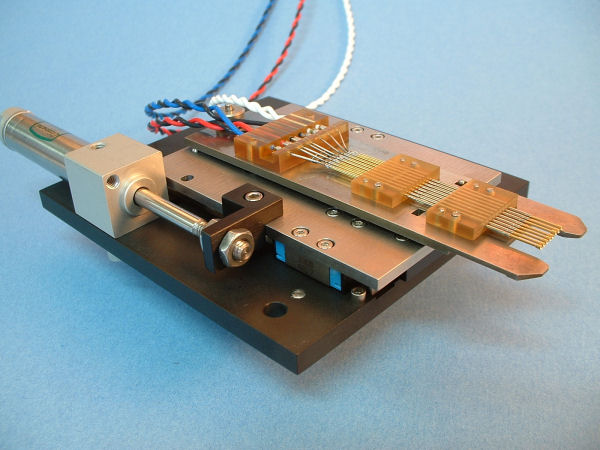

Automated probe contactor for making contact with connector on the LED package.

Side view of probe contactor.

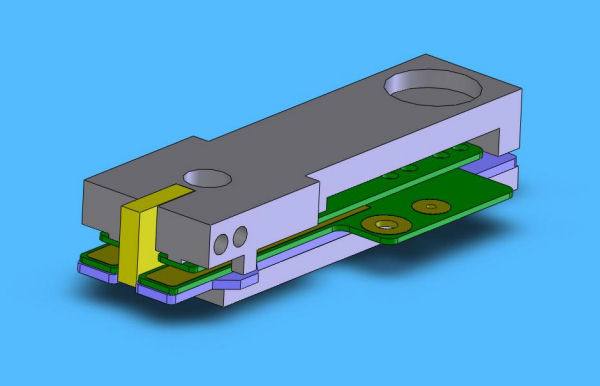

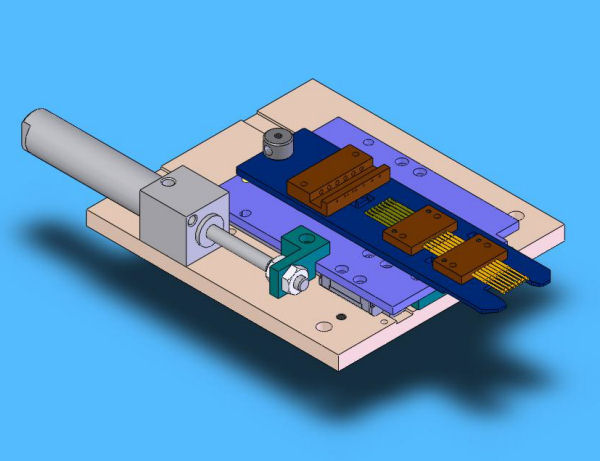

Solidworks assembly of the probe contactor.